Sheet Equipment,Plastic Profile Production Line,Geocell Machine,Root Controller Machine,Seedling Tray Machine,Board Equipment,Blister Packaging Machines,PLA Degradable Plastic Sheet Machine,Car Mat Production Line,Soft Door Curtain Machine,pipe production line

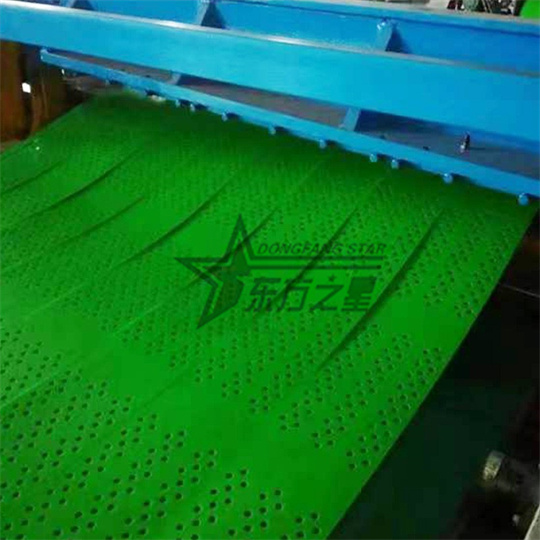

In the world of modern construction and civil engineering, the demand for robust, durable, and cost-effective solutions has never been higher. Qingdao Eaststar Plastic Machinery Co., Ltd. stands at the forefront of innovation with its state-of-the-art Geogrid Extrusion Equipment. This advanced machinery is engineered to produce high-quality geogrids—a critical component in soil reinforcement, slope stabilization, and erosion control. By integrating cutting-edge technology with decades of expertise, our equipment ensures unmatched performance, enabling industries to build safer, more sustainable infrastructures. Whether for highways, railways, or environmental projects, this machine delivers precision and efficiency, making it an indispensable asset for progressive businesses.

Geogrid Extrusion Equipment by Qingdao Eaststar Plastic Machinery Co., Ltd." />

Geogrid Extrusion Equipment by Qingdao Eaststar Plastic Machinery Co., Ltd." />

What sets Qingdao Eaststar's Geogrid Extrusion Equipment apart is its holistic approach to quality and innovation. Crafted from premium-grade materials, the machine boasts a rugged construction that withstands harsh operational environments. Its intelligent control system allows for seamless automation, reducing human error and enhancing productivity. With features like real-time monitoring and energy-efficient motors, users experience significant cost savings over time. The equipment's modular design facilitates easy maintenance and upgrades, ensuring long-term reliability. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs every unit with comprehensive after-sales support, including training and spare parts availability, so clients can focus on their core projects with confidence.

Many construction projects face delays and budget overruns due to inconsistent material quality or inefficient production processes. Our Geogrid Extrusion Equipment tackles these issues head-on by offering a streamlined, high-output solution. For instance, in scenarios where traditional methods lead to weak geogrids prone to deformation, this machine ensures uniform tensile strength and dimensional accuracy. Below is a detailed parameter table highlighting key specifications that address common pain points:

| Parameter | Specification | Benefit |

|---|---|---|

| Output Capacity | Up to 500 kg/h | High efficiency for large-scale projects |

| Power Consumption | Optimized at 100-150 kW | Reduces operational costs |

| Extrusion Accuracy | ±0.5 mm tolerance | Ensures consistent product quality |

| Material Compatibility | PP, HDPE, and other polymers | Versatile for various applications |

| Automation Level | Fully automated with PLC control | Minimizes manual intervention |

The Geogrid Extrusion Equipment by Qingdao Eaststar Plastic Machinery Co., Ltd. is ideal for a diverse range of professionals and industries. Civil engineering firms, infrastructure developers, and environmental agencies find it invaluable for projects like road construction, landfill lining, and coastal protection. Contractors working on tight deadlines appreciate its rapid production cycles, while sustainability-focused teams value its ability to create eco-friendly geogrids that reduce soil erosion. From urban planners to agricultural innovators, anyone involved in geotechnical applications can leverage this equipment to achieve superior results, ensuring projects are completed on time and within budget.

Imagine the satisfaction of completing a major infrastructure project without the usual setbacks. With Qingdao Eaststar's Geogrid Extrusion Equipment, users report a sense of reliability and peace of mind. It eliminates the frustration of equipment downtime and subpar materials, allowing teams to meet stringent safety standards and environmental regulations. Clients often share how this machinery has helped them overcome challenges like unstable ground conditions, leading to longer-lasting structures and enhanced community trust. By investing in this equipment, businesses not only improve their bottom line but also contribute to safer, more resilient infrastructures that stand the test of time.

While many manufacturers offer geogrid production tools, Qingdao Eaststar Plastic Machinery Co., Ltd. distinguishes itself through innovation and customer-centric design. Unlike standard models, our Geogrid Extrusion Equipment incorporates adaptive cooling systems that prevent material warping, a common issue in high-temperature operations. Additionally, the integration of IoT capabilities enables remote diagnostics and predictive maintenance, reducing unexpected breakdowns. The company's commitment to research and development means continuous improvements, such as enhanced energy recovery systems that lower carbon footprints. These unique features, combined with competitive pricing, make it a top choice for forward-thinking enterprises.

What types of materials can the Geogrid Extrusion Equipment process?

The equipment is compatible with a wide range of polymers, including polypropylene (PP) and high-density polyethylene (HDPE), allowing for flexibility in producing geogrids suited to different environmental conditions and project requirements.

How does the automation feature improve operational efficiency?

With fully automated PLC controls, the machine minimizes manual input, reduces errors, and maintains consistent output quality. This leads to higher productivity, lower labor costs, and the ability to run continuous operations with minimal supervision.

What kind of maintenance does the equipment require?

Regular maintenance includes cleaning extruder components, checking electrical systems, and lubricating moving parts. The modular design allows for easy access, and Qingdao Eaststar provides detailed manuals and support to ensure optimal performance and longevity.

Can the equipment be customized for specific project needs?

Yes, Qingdao Eaststar Plastic Machinery Co., Ltd. offers customization options for output capacity, material types, and control systems. Clients can work with our engineering team to tailor the equipment to their unique applications.

What safety features are included in the design?

The equipment comes with emergency stop buttons, overload protection, and insulated electrical components to ensure operator safety. Regular updates and compliance with international standards further enhance its safe operation in various settings.

How does this equipment contribute to environmental sustainability?

By producing high-quality geogrids that improve soil stability and reduce erosion, it supports sustainable construction practices. Additionally, the machine's energy-efficient design lowers power consumption, aligning with green initiatives.